Gear Drive Trainer MT-30-05-06Description

Request A Quotation

- Description

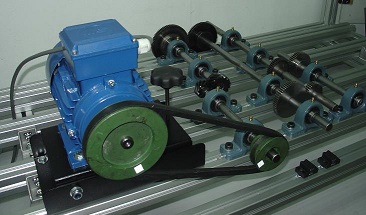

Description

INTRODUCTION

Comprehensive package of mechanical training system MT-5000 combines the best features of five proven EDU-LABS mechanical training systems MT-10 Series, MT-20 Series, MT-30 Series, MT-40 Series and MT-50 Series in one hands-on workstation. The system allows the student to progress through the full range of common mechanical skills using one comprehensive training system.

GENERAL DESCRIPTION

- This versatile assembly allows for convenient hands-on training in gear identification, installation, alignment, and troubleshooting.

- The device includes a diverse selection of industrial-quality gears, shafts, and bearings, allowing for use in a variety of configurations.

- The welded aluminum and CNC machined gear box provides for mounting and shimming of tapered roller bearings using several different bearing housing types.

- Useful in the classroom or training lab, this heavy-duty device will improve maintenance skills, as well as increase the understanding of precision gearing.

FEATURES AND SPECIFICATIONS

- 7-Gauge, formed-steel baseplate with provision for tabletop mounting.

- Welded aluminum gear box, allowing for installation of all supplied gear sets.

- Seven custom bearing housings allowing for installation and shimming (internal and external) of tapered roller bearing sets.

- Two additional flanged bearing units for open gearing application.

- Gear sets, including spur gears, helical gears, worm/worm gear, and bevel (miter) gears. Gear sets include different pitches, ratios, pressure angles, and pitch diameters.

- Steel bracket for mounting dial indicator, for backlash measurements

- Bearings, including tapered roller bearings and radial ball bearings.

- Shafting with keyways and keys.

- Handle for illustrating thrust and establishing wear patterns.

- High-durability, powder-coated surfaces throughout.

- Crating for shipment via motor freight.

EXPERIMENTS LISTS

Gear Drives 1

- Lab Sheet 1: Introduction to Gear Drives

- Lab Sheet 2: Spur Gear Installation, Alignment and Backlash Adjustment

- Lab Sheet 3: Speed and Gear Ratios

- Lab Sheet 4: Introduction to Gear Trains

- Lab sheet 5: Introduction to compound gear trains

Gear Drives 2

- Lab Sheet 1: Helical Gears

- Lab Sheet 2: Worm Gears

- Lab sheet 3: Bevel gears

- Lab Sheet 4: Miter Gears

- Lab Sheet 5: Gearboxes

- Lab Sheet 6: Repair and maintenance

Note: Due to products continuous development process, layout and specification may change without prior notices.