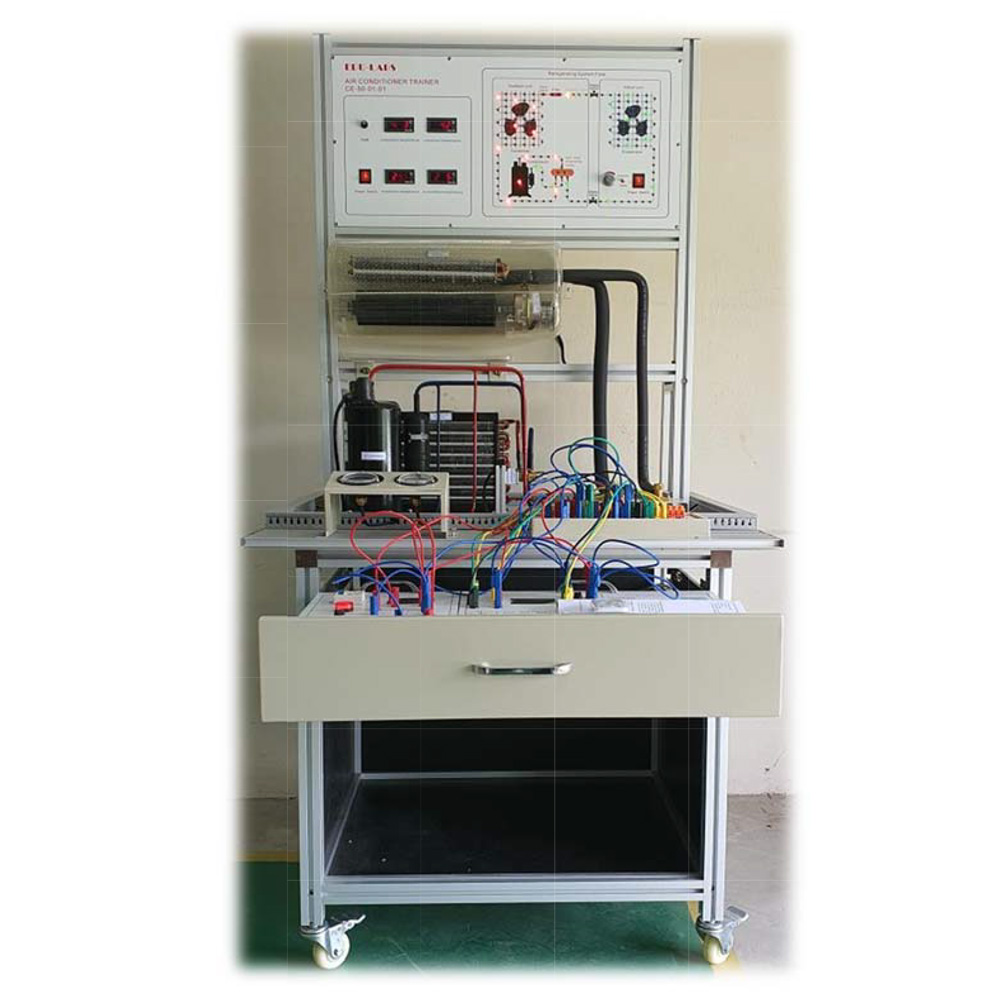

Air Conditioner Trainer CE-50-01-01Description

- Movable air conditioner system trainer built on one aluminum alloy profile, with drawer type electrical controlling system saving space and easy for operation.

- High/low pressure pipelines marked with colors for easy identification, special designed testing points on each key position for fast pressure measuring connection via HP/LP gauge group.

- Centralized wiring terminal box for easy electrical arrangement, coming with 4mm safety sockets and code number.

- Refrigeration flow on top panel, indicating the high pressure and low pressure states with related meters for real time temperature display of key positions.

TRAINING CONTENT

- Air conditioning system pipeline construction

- Wiring of Air Conditioner electrical system

- Coolant state tracking and its relationship with pressure

- System vacuumization and coolant charging

- System air tightness testing

- Thermodynamics elements application

- Application of air conditioning system maintenance tool

- Description

Description

CONFIGURATION

1. Training Platform

– Guide rail type aluminum alloy frame

– Terminal blocks

– Cabling channel

– Drawer

– Universal lockable wheels

– Dimension: 960mm × 825mm × 1880mm (approx.)

2. Power Supply Panel

– Input: 1PH 240V±10%, with short circuit / leakage protection and power indicator

– Output: 2-way 240V universal output sockets

– Digital display: 0…250V and 0…5A current indication

– Safety 4mm sockets for power in/out

– Painted panel with carrying handles

3. Air Conditioner Electrical Control

– Sensor: indoor temperature sensor, pipeline temperature sensor

– Capacitor: outdoor/indoor fan capacitor, compressor capacitor

– Working indicator: red, blue, yellow

– Others: push button, 5A fuse, etc.

– Painted panel with carrying handles

4. Air Conditioner System Demonstration Board

– Aluminum alloy frame 40mm×40mm

– Digital thermometer for compressor / condenser / evaporator / environmental temperature display – System work flow indicators (red, green, yellow)

– Rotary knob, rocker switches, fuse protector, etc.

– Printed board

5. System Pressure Detection Unit

– High pressure side vacuum manometer: -0.1-3.8MPa

– Low pressure side vacuum manometer: -0.1-1.8MPa

– Steel support, fixed by hexagon socket head cap screws

6. Air Conditioner System

– Rotary compressor (R22)

– Four-way reversing valve

– Air control valve

– Indoor heat exchanger

– Throttling device

– Outdoor heat exchanger

– Sight glass

7. Connecting Lead: 4mm Safety Stackable Test Leas Sets

8. Tool Kit

1). Portable welding torch

2). Rotary-vane vacuum pump

3). Pipe bender

4). Dual-Gauge Valve

5). Adapter Suite

6). Wrench

7). Measuring Tape

8). Charging hose

9). Allen Key Set

10). Expand tube reamer

11). Cutting-off tool

12). Chamfering tool

Note: Due to products continuous development process, layout and specification may change without prior notices.