Auto PCB Prototyping Machine EP-42AUTODescription

ONE KEY PROCESS. A NEW GENERATION OF ADVANCED PCB MAKING.

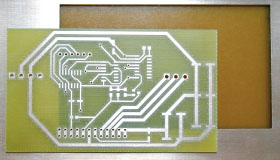

- Apply to : RF / Microwave / High Frequency / Digital / Analogy / Manufacture Fixtures.

- Double and single sided circuit board prototype.

- Motorized Z-axis with AI control monitors by PC.

- Easy operation with vision align system.

- Support GERBER and DXF format.

| Working Area | 230 x 320 mm |

| Axes | X.Y.Z |

| MAX. Travel Speed | 60 mm/sec |

| MAX. Working Speed | 30 mm/sec |

| Drilling Performance | 120 Stroke/min |

| Tool Holder | 1/8″ Socket |

| Surface Detect | Auto Surface Detect |

| Weight | 60 Kg |

| Power Consumption | AC 110~220 V |

| Resolution (X/Y) | 0.5 µm |

| Control Motor | X.Y.Z / Stepping Motor |

| MIN. Trace Width | 4 mil |

| Drilling | 0.2~3.175 mm |

| Tool Change | Automatic 12 positions |

| Tool Length Detect | Auto Tool Length Detect |

| Spindle Speed | 5,000~42,000 rpm (Software Control) |

| Dimension | W735xD500xH497 mm |

For more examples, please click here Practical application example

Request A Quotation

- Description

Description

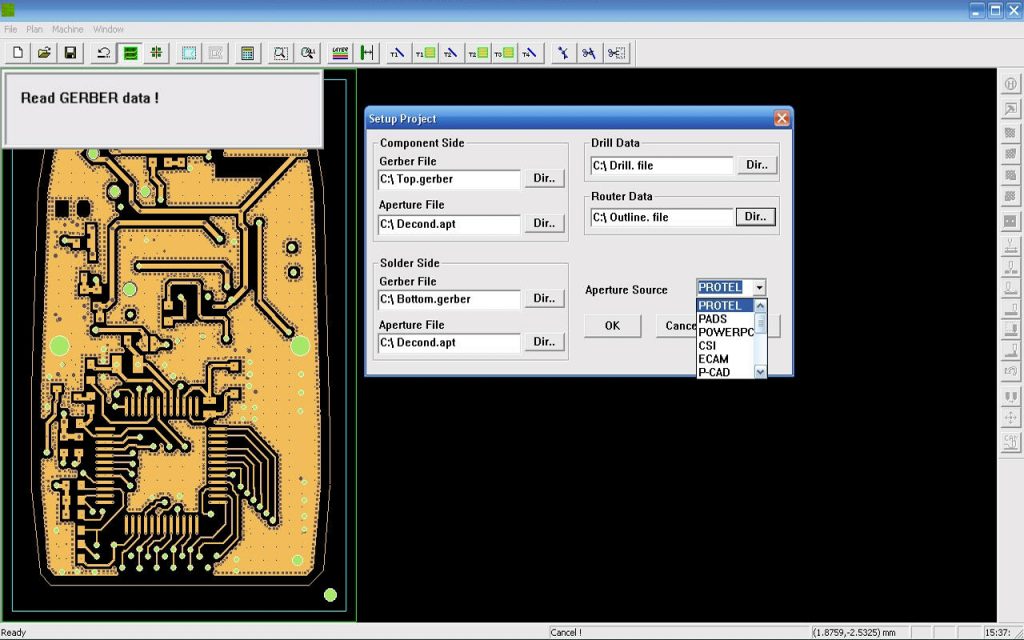

PCAM Software

PCAM is compatible with all windows system and accepts standard RS274D/X format GERBER files exported from layout software like: PROTEL / ALTIUM DESIGNER / P-CAD / ALLEGRO / POWER PCB (PADS) / ORCAD, etc.

Import Gerber Files

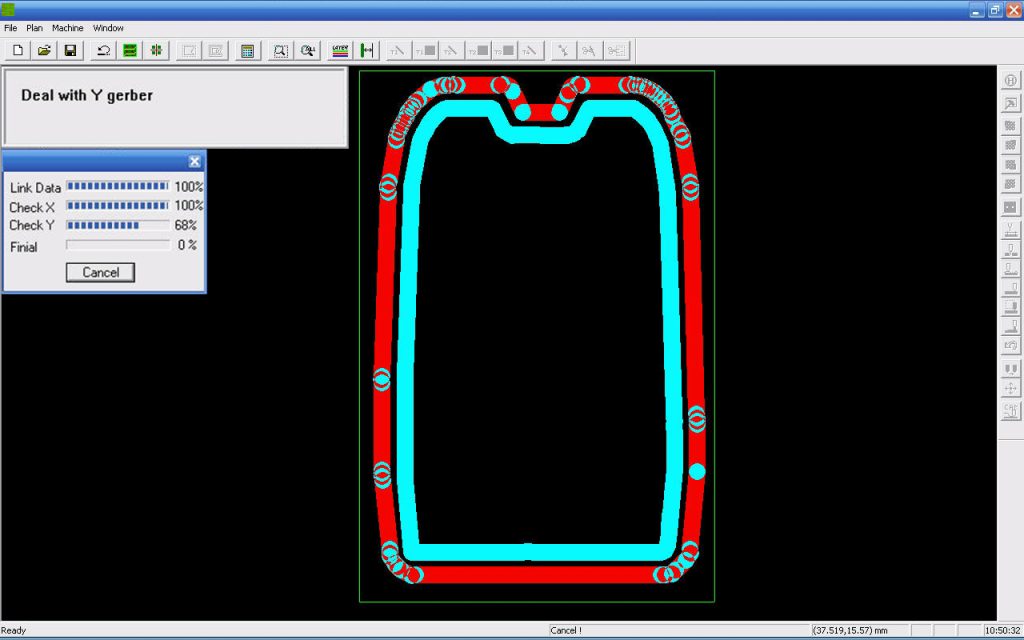

Routing Setup

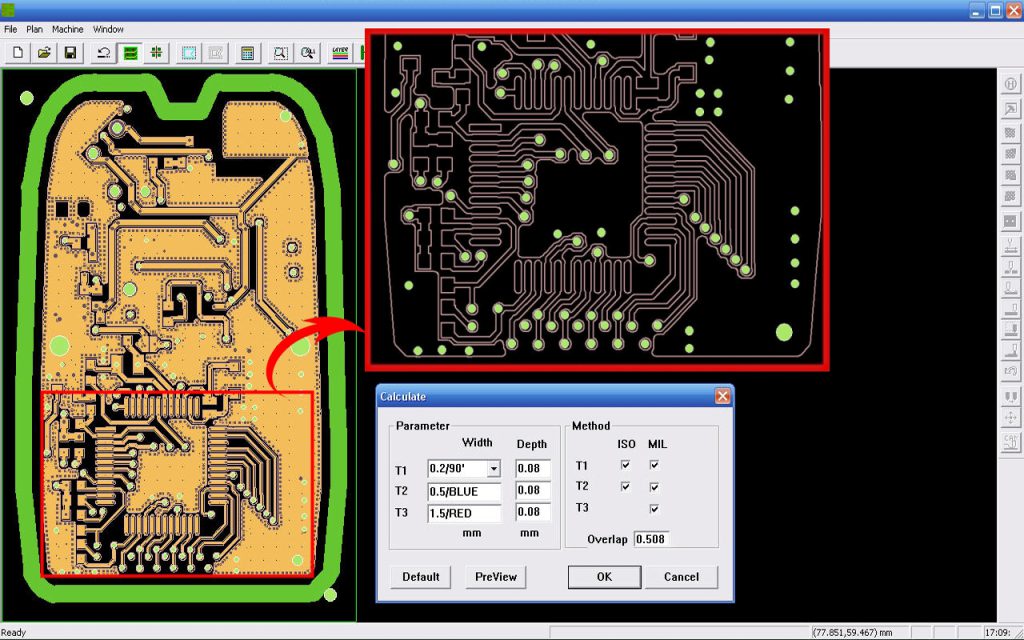

Calculating Engraving Path

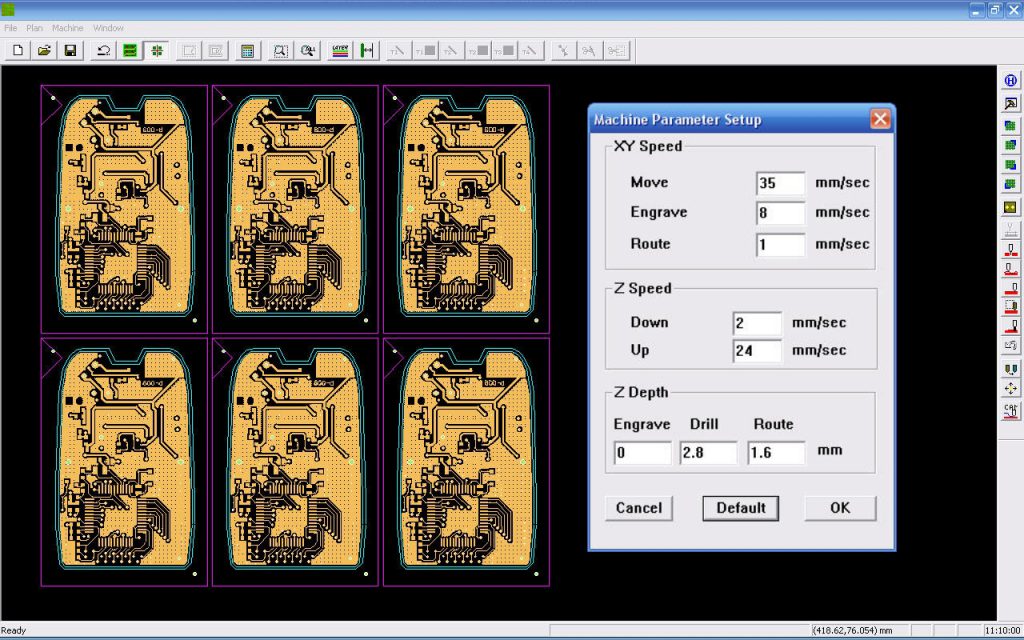

Engraving Setup

PROCESS OF PROTOTYPING

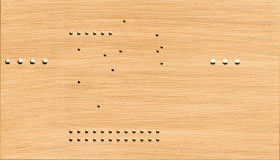

1. PCB Drilling

Machine will do drilling each hole size by your demand.

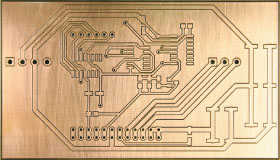

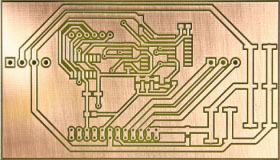

2. T1

60 or 90 degree engraves tool isolates pads or traces

3. T2

Milling tool makes wider trace and removes copper.

4. T3

Milling tool removes big area copper.

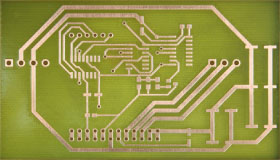

5. PCB Routing

Cutting outline of the PCB.